Idea Bulletin

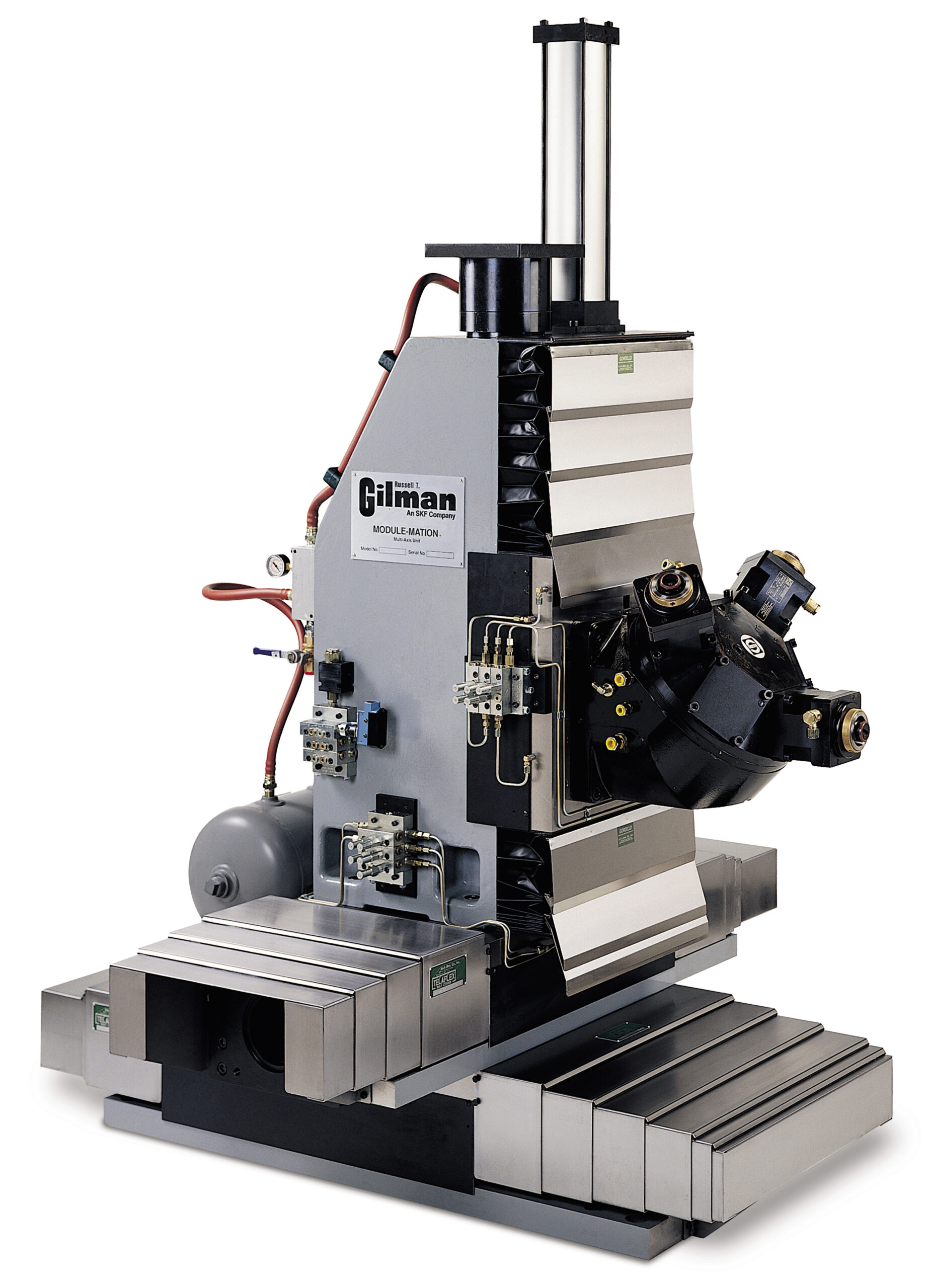

Turret Head Increases Multi-Axis Flexibility Multi-axis module with turret head, a perfect fit in small rotary cell

Application

A builder of special, dial-type machining cells needed to apply multiple tools to a single work piece within a 400mm work envelope. In this automotive manufacturing situation -- facing and deburring engine exhaust manifolds -- the cell was expected to achieve short cycle times with accuracy and high reliability.

Challenge

To keep cycle times short and stability high, the builder wanted to keep the dial plate as small as possible. That meant each station would need to have a small footprint. It also meant that a storage rack and tool transfer mechanism of a traditional tool changing system would be very difficult to fit into the deburring station

Solution

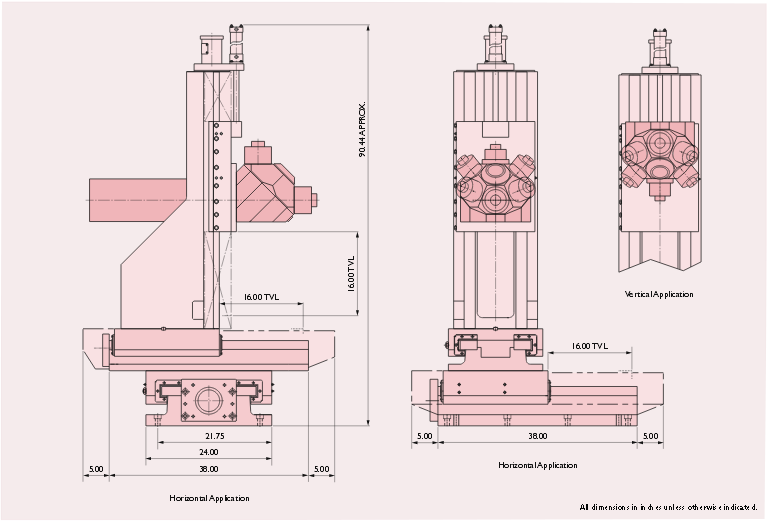

Gilman’s 400mm work envelope, multi-axis machining module was an ideal choice. Its proven, rugged design and small footprint fit right in. The ability to have either the X or Z axis as the unit’s base gave the customer even more choices. The slides were Gilman’s hardened way design, with a HWL24-20-38-SM3-16 as the base and HWL18-20- 38-SM3-16 as the cross slide. The tool changing needs for the application were handled masterfully by the installation of a turret head. The design allowed the application of as many as six tools (HSK or ABS Mounting) to the work piece without physically

removing and reinserting any tools. The turret head met all the customer’s tool changing needs. Gilman was even able to offer the builder a choice of orientation of the turret. The head could be mounted so the working spindle position was horizontal or vertical (nose down). It was also possible to offer the customer a four position turret at a lower cost than the six position unit(Consult Gilman for prices). Spindle speeds could be as high as 10,000 RPM depending on tools and application. The customer specified the axes drive motors and integrated theunit with the cell’s CNC control. Gilman continues to offer the fixed spindle version of the product. A 40 Taper belt driven spindle or 40 Taper motorized spindle (170mm cartridge size)is standard. Motorized spindles could be either the GHS 170 high speed unit or the GLS 170 low speed design (see catalog 1199 for details).

Technical Specifications

Slide:

• HWL24-20-38-SM3-16

• HWL18-20-38-SM3-16

• Ground ball screws with preloaded nut

• Axes drive motors provided by customer

Spindle Selection:

• 4 or 6 position turret head

• Motorized spindle, 170mm GLS/GHS

• 40 Taper, belt-driven

RPM Range:

• Turret head maximum speed 10,000 RPM

• GLS 170 maximum speed 9,000 RPM, 5.5 kW

• GHS 170 maximum speed 24,000 RPM, 22 kW

• 5500 (belt-drive) maximum speed 9,200 RPM

Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect, or consequential arising out of use of the information contained herein.

Request A Quote

To request a quote, please contact us using the contact form.

If you have an item that we can repair for you, click the repair request forms below.

Use our product configurator to download a drawing to use in your design.

If you you would like to reach us directly, give us a call at 262-377-2434, or email us at sales@gilmanprecision.com.