Hardened Way Slides Provide Durability for Long-Life Operations

Gilman Precision explains the basics of a hardened way slide, including which applications they are good for and how to keep yours in great working condition.

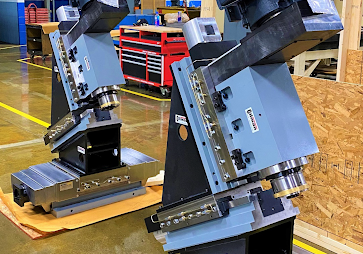

Predominantly used for high production, hardened way slides provide linear rigidity for heavy duty applications.

“A hardened way slide is a linear positioning device that incorporates precision, ground rectangular way guides,” said Gilman CEO Chris Hetzer. “It is used when accuracy, dampening and rigidity are required while positioning.”

The amount of friction created by a hardened way slide and a linear guide slide is the prime difference. A linear guide slide is guided by rolling elements, either ball or cylindrical rollers. These rollers allow the slide to operate with zero friction, creating less heat, and therefore move faster.

In contrast, hardened way slides are guided by the plain bearing, leading to more area of direct contact. This generates more friction and decreases speed, but tremendously increases durability.

A hardened way slide has hardened and ground replaceable way guides, Hetzer explained. The moving member, called the saddle, has ground and oil grooved low friction bearing material, for smooth, accurate motion and high rigidity.

“To keep your hardened way slide performing as designed, keep the way guides clean from chips and dirt,” Hetzer said. “Make sure the wipers that clean the rectangular way guides are in good working order. Also, lubrication is a must, using Mobil Vactra No. 2 or an equivalent type of oil. Never use grease as a lubricant on a hardened way slide.”

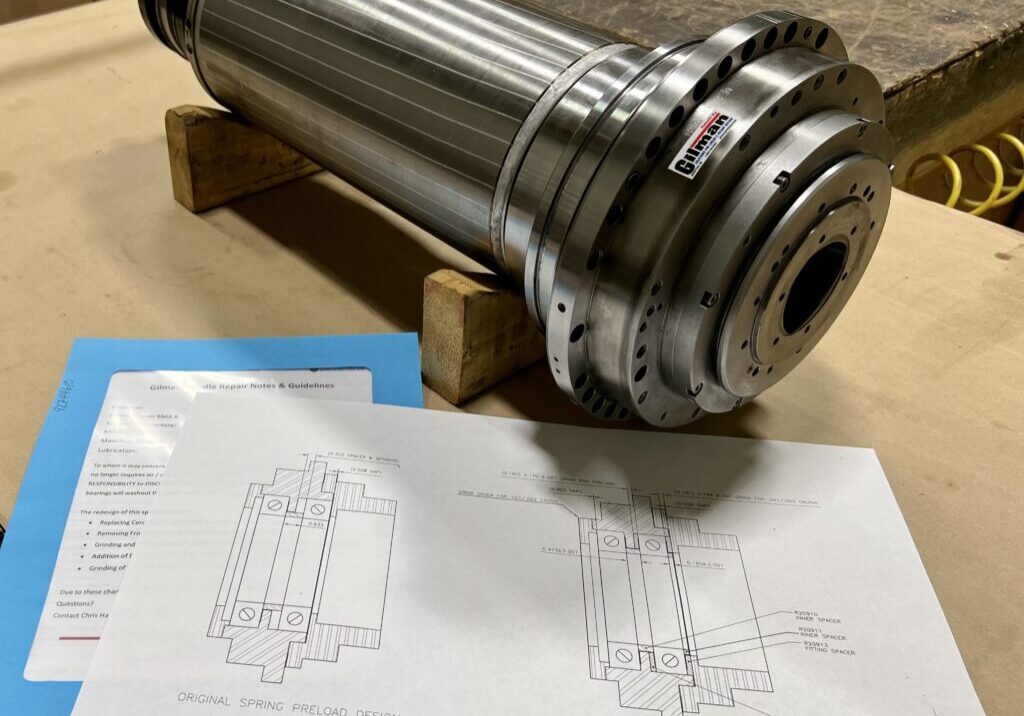

Gilman Precision has been dedicated to the advancement of high precision solutions that improve efficiency and achieve longevity since 1952. The company develops customized slides and spindles for value-added engineers with exacting needs and standards, providing expert service for virtually any manufacturer’s equipment.

If you’ve got a question on ordering a hardened way slide, contact us at 800-445-6267 or sales@gilmanprecision.com.