Gilman Precision Announces Solar Project In Grafton

Partnership with Energy Management Leader, Arch Electric, to cut Energy Costs by 46%

(Grafton, Wisconsin, May 27, 2021) Wisconsin manufacturing company, Gilman Precision, which specializes in motion control for production equipment, announced their plans to install a 1026-panel Solar Photovoltaic System on their property in Grafton, Wisconsin. Gilman’s ground-mounted system will help it reduce its municipal power needs by generating a predicted 493MWh in annual renewable energy.

With recent decreases in equipment and installation costs, solar investments are becoming more accessible to companies of all sizes. A shorter wait to recognize a financial return from the project was just one of the incentives for Gilman. CEO and Owner of Gilman Precision, Chris

According to estimates, this solar project will save roughly 360K pounds of coal from being burned (based on CO2 emissions) each year. Once installed, the panels will reduce Gilman’s energy costs by 46% annually. The company intentionally set the energy goal from the solar panels at less than their total usage because battery technology for storage is inefficient and not as environmentally friendly.

Ground has broken on the 2.5-acre project that may take up to 6 months to be completed. The panel farm will be installed on the West Lot of the Gilman Precision complex, land that was previously unused. As a side benefit to the energy and cost advantages, solar panel installation also aids in environmental health by providing improved pollinator habitat through reduced landscaping.

Gilman Precision values corporate and community responsibility as an integral part of American Manufacturing excellence. The investment in solar energy is the latest in their commitment to sustainability, which also includes metal and coolant recycling, facility relamping with LED, and HVAC replacement with more efficient units and use of environmentally friendly freon.

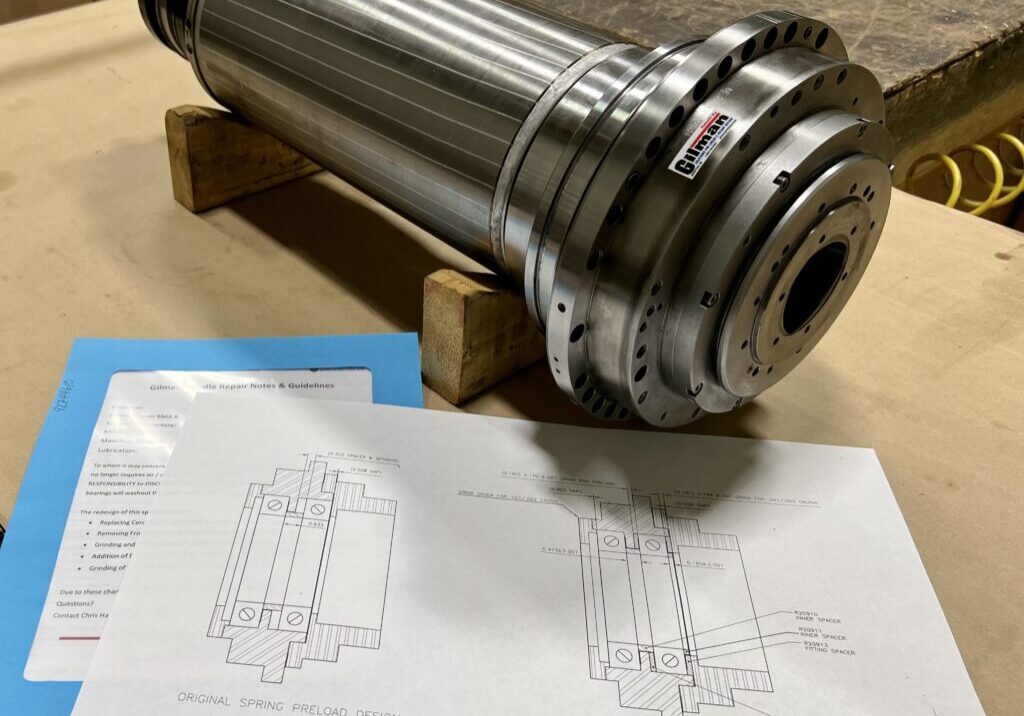

Gilman Precision designs, produces, and repairs spindles and slides for industrial automation requiring hyper-accurate, ultra-smooth motion control. Gilman’s quality standards and expertise have won them customers from the most exacting industries, including aerospace, automotive and medical industries. For nearly 70 years, Gilman has been responsibly growing American Manufacturing through their commitment to excellence and culture of community.